Shipping Point Determination in Cross-Company STO | Configuration Guide [Part 3]

In this part of the configuration, focused on how SAP determines the Shipping Point, a crucial element that drives outbound delivery creation from the supplying plant in an STO process.

Shipping Point is determined based on three key factors, all of which must align correctly in your master data and configuration. Let’s explore them one by one with the help of real-time screenshots.

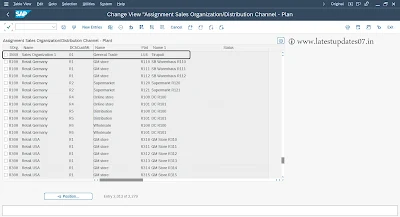

In this step, we assign the Sales Organization, Distribution Channel, and Plant to define the sales area responsible for processing outbound deliveries and billing in the Cross-Company Stock Transport Order scenario. This configuration ensures proper linkage between logistics and sales modules, allowing the supplying plant to behave like a delivering sales entity.

This setting is especially critical when the supplying plant is tied to a different company code and needs to generate an outbound delivery followed by an intercompany invoice.

Refer to the screenshot given below.

In the Cross-Company STO configuration process, assigning a Shipping Point to a Plant is a crucial step. This setting tells SAP which shipping point is responsible for handling outbound deliveries from the supplying plant.

Shipping point determination is influenced by three key factors:

- Shipping condition – Defined in the customer master for the receiving plant

- Loading group – Maintained in the material master for the sales: general/plant view

- Supplying plant – The physical location from where goods are shipped

By correctly assigning the shipping point to the supplying plant, SAP ensures accurate delivery processing, optimized scheduling and smooth logistics execution.

Refer to the SPRO navigation path screenshot given below to configure this setting.

In this part, I explored how SAP determines the Shipping Point during a Cross-Company Stock Transport Order (STO) process. We discussed the three critical factors that influence this determination:

- Shipping Condition – Maintained in the Customer Master, representing how the goods should be delivered (e.g., pickup or delivery).

- Loading Group – Defined in the Material Master (Sales: General/Plant view) indicating how the goods are loaded.

- Supplying Plant – The plant responsible for shipping the material.

Additionally, we navigated through key configuration steps, such as:

- Assigning Sales Organization – Distribution Channel – Plant

- Defining and Assigning Shipping Points

- Linking Shipping Points to Supplying Plants

These settings ensure that the system can accurately propose a shipping point during delivery creation in the STO flow.

Proper configuration of shipping point determination is essential for automated and error-free outbound delivery processing in cross-company procurement.

Part 1 : SAP Cross Company STO with Billing | Configuration Guide Part 1

Part 2 : SAP Cross Company STO with Billing | Configuration Guide Part 2

If you found this post helpful:

✅ Bookmark this page

✅ Share it with your team or network

✅ Visit regularly | upcoming posts in this series will be linked below as soon as they go live.

📢 Coming Up Next:

🔗 Part 4 – STO Delivery & Billing Configuration (Coming Soon...)

Please keep these guidelines in mind when commenting:

Stay On Topic:

Comments should be relevant to the blog post’s subject, focusing on SAP, Microsoft Dynamics 365 FO.

No Promotions or Spam:

Promotional messages, irrelevant links and spam comments will be removed to keep the discussion valuable.

Privacy Reminder:

Please avoid sharing sensitive or personal data in your comments.